| Model | Chamber Volume (L) | Internal Dimensions (W × D × H, mm) | DIN 1/1 (480×250 mm) | DIN 1/2 (480×125 mm) | Typical Use Case |

|---|---|---|---|---|---|

| VS-35R | 35 L | 320 × 250 × 450 | 1 | 2–3 | Dental, labs |

| VS-50R | 50 L | 350 × 300 × 475 | 2 | 4 | Clinics, mobile units |

| VS-75R | 75 L | 400 × 350 × 530 | 3 | 6 | Outpatient centers |

| VS-100R | 100 L | 450 × 370 × 600 | 4 | 8 | OR prep, CSSDs |

| VS-120R | 120 L | 450 × 400 × 670 | 5 | 10 | Private hospitals |

| VS-150R | 150 L | 500 × 420 × 720 | 6 | 12 | Hospital ORs |

| VS-200R | 200 L | 550 × 450 × 800 | 8 | 16 | CSSDs, day clinics |

| VS-250R | 250 L | 600 × 470 × 880 | 10 | 20 | Multi-OR facilities |

| VS-300R | 300 L | 650 × 500 × 900 | 12 | 24 | Regional hospitals |

| VS-400R | 400 L | 700 × 500 × 1150 | 14 | 28 | Large CSSDs |

| VS-500R | 500 L | 750 × 550 × 1200 | 16 | 32 | Medical centers |

| VS-600R | 600 L | 800 × 550 × 1350 | 20 | 40 | Tertiary hospitals |

| VS-750R | 750 L | 850 × 600 × 1450 | 24 | 48 | Sterilization hubs |

| VS-1000R | 1000 L | 900 × 650 × 1700 | 30–32 | 60–64 | National-level CSSDs |

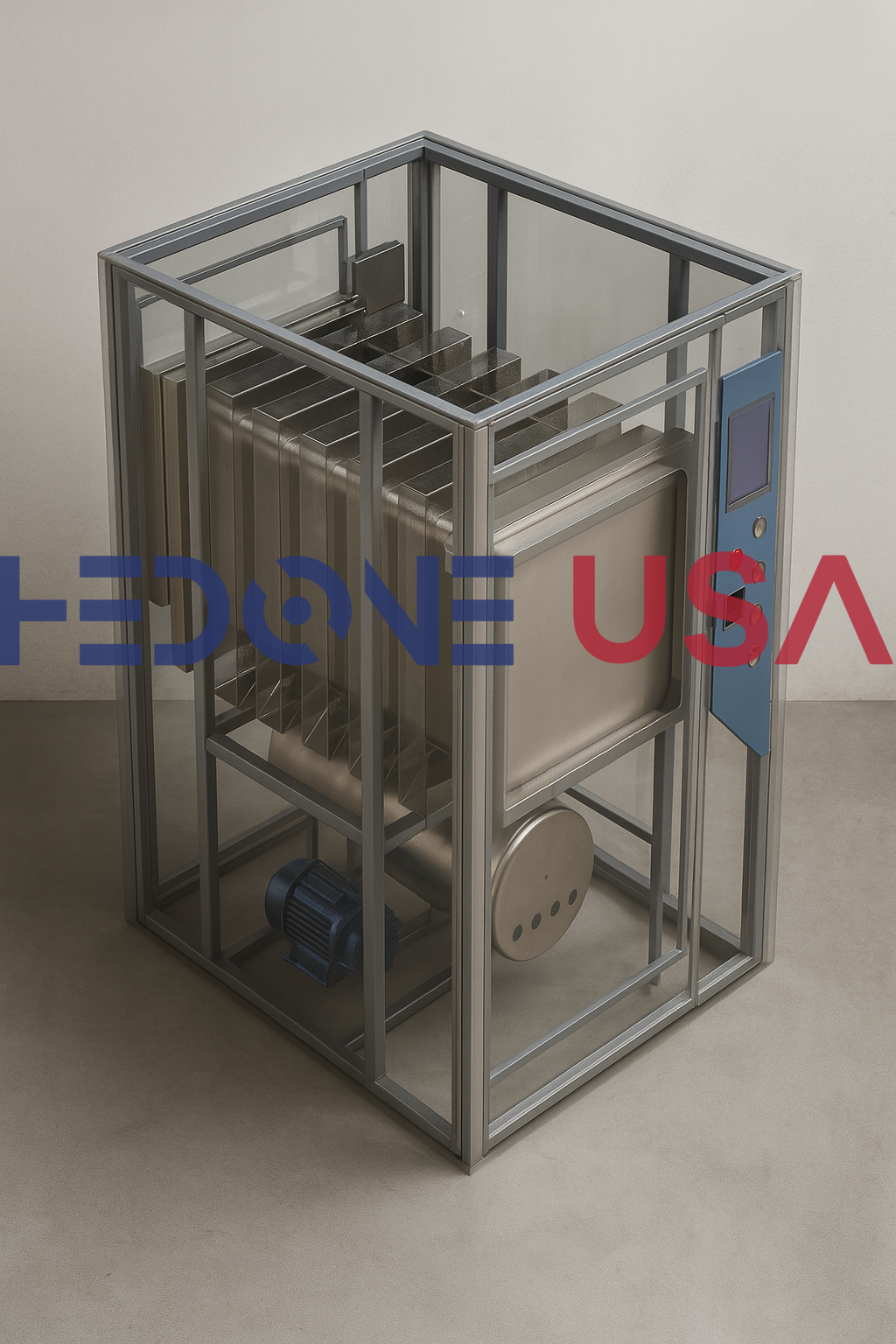

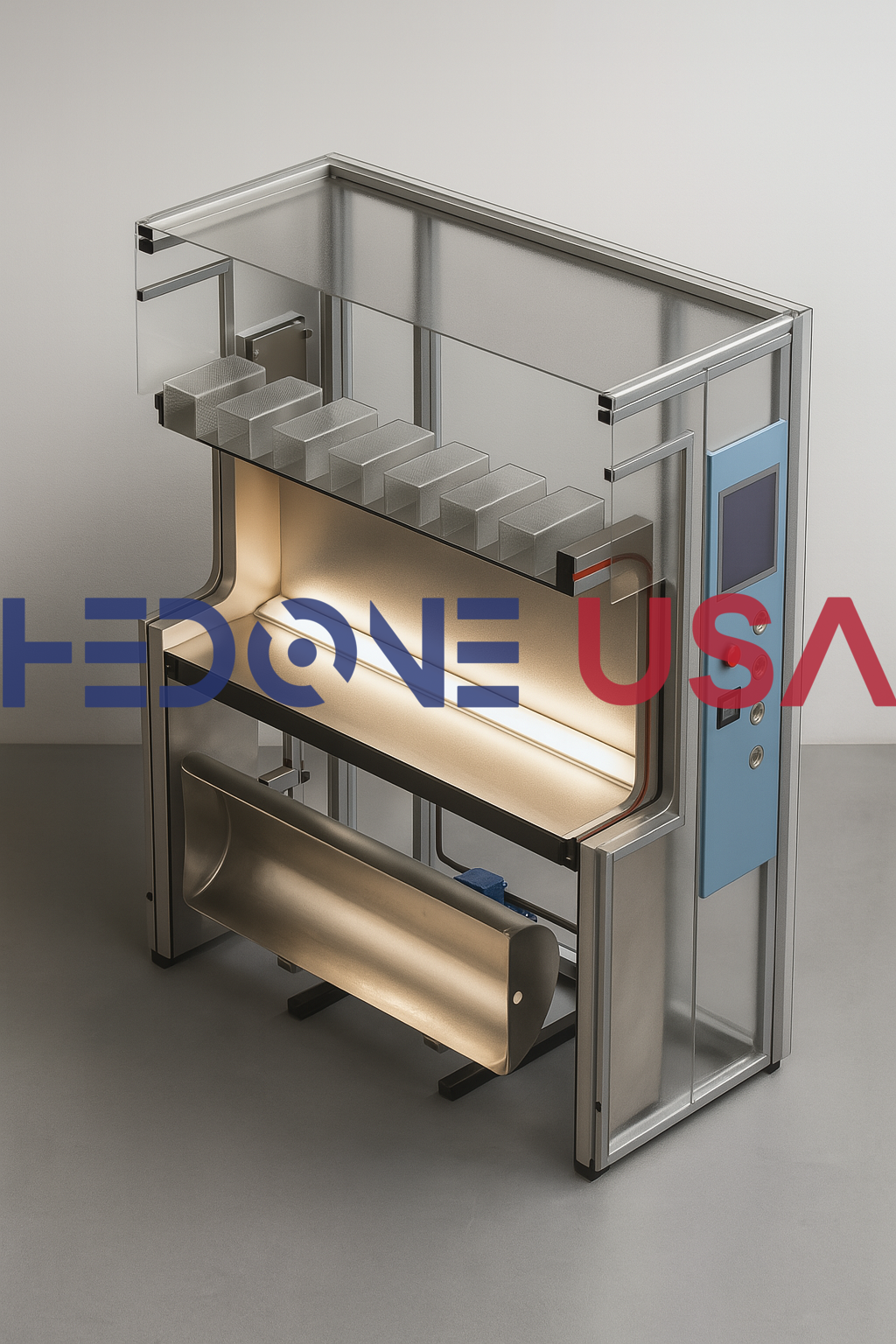

Chamber Construction: High-grade SUS 304 or SUS 316L stainless steel, polished and corrosion-resistant

Lid Design: Pressure-resistant vertical lid with radial locking arms, safety interlock mechanism, and silicone gasket

Sterilization Temperature: 121°C and 134°C cycle presets with ±1°C temperature accuracy

Operating Pressure: 0.22 MPa (2.2 bar) nominal operating pressure

Steam Source Options: Integrated electrical steam generator (standard) or external steam inlet (optional)

Control Interface: Microprocessor-based digital display / Touchscreen PLC with user-friendly navigation and multiple cycle storage

Cycle Types:

Wrapped/unwrapped solid instruments

Liquids in open containers

Porous load (optional vacuum pump required)

Glassware & media

Drying Function: Optional hot air or vacuum drying for enhanced instrument turnaround

Water Feed: Manual or automatic water filling (RO/DI compatibility supported)

Chamber Drainage: Thermostatically controlled with heat protection and antibacterial trap

Printer/Data Logging: Real-time printout or USB export for cycle validation and traceability

Manufactured under ISO 13485 and ISO 9001 Quality Systems

EN 13060 or EN 285 (depending on model class)

CE Marked – MDR Compliant

FDA 510(k) documentation package (for U.S. market)

IQ/OQ/PQ Validation Package available upon request

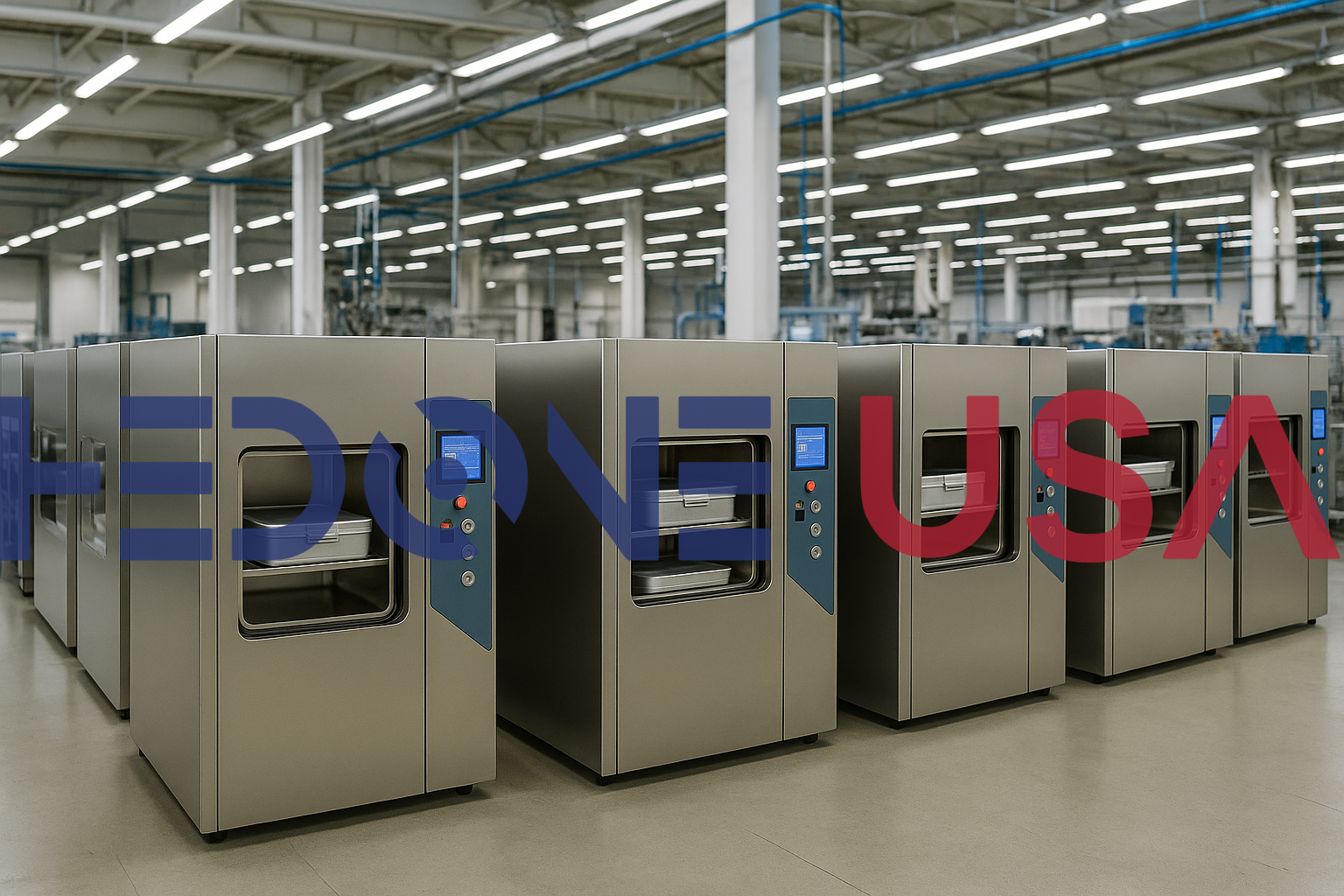

Let HEDONE USA become your OEM sterilizer manufacturing partner, offering U.S.-level engineering, global compliance, and industrial durability.

Contact us now to receive the technical dossier, MOQ, lead time, and price quotation.

Custom branding (logo, interface, panel design, color scheme)

Turnkey documentation for regulatory submission

Rapid lead times with short-run or high-volume manufacturing

Engineering support from prototype to scale

Spare parts availability & logistics coordination

U.S.-based representation and after-sales coordination